Author: |

The physics of femtosecond laser heating of gold films has been the focus of scientific research for many years due to the large number of applications. Gold coating optical multi- layer thin films are important components in many optoelectronic devices. Especially in the field of femtosecond laser, the gold film surface is irradiated by femtosecond laser, the lattice temperature of the substrate metal rises due to the absorption of the incident laser in the gold surface region.

Prof. Wang Tingfeng and Pro f. Guo Jin performed a series of numerical simulations of femtosecond laser processing of Au film deposited on Cu substrate with 1000 nm thickness, using the finite difference method. The distributions of electron temperature and lattice temperature were considered. The calculated results showed that the thickness of gold layer had a very important influence for the distribution of the film temperature.

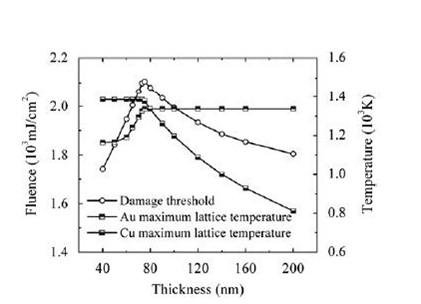

They use the well-known two-temperature model (TTM) to simulate the process. They calculated the variation of the damage threshold with the gold thickness. The results are presented in the Fig. 1

Fig.1.Damage threshold (leftaxes), Au layer maximum lattice temperature(right axes), and Cu layer maximum lattice temperature(right axes) recorded for various thickness of Au layer.

So, they find the desired temperature distribution under the femtosecond laser heating by increasing or reducing the thickness of the coated layer. Moreover, the investigated result of the damage threshold showed that the maximum damage threshold can be obtained by changing the thickness of the coated gold. The results can be used to optimize the damage threshold of gold coating optical components (mirror and grating), especially for high-power femtosecond laser system.

These findings has been published in Optics&LaserTechnology, 44(2012) 1551-1555.