Author: |

Recently one of CIOMP research group have made great effort to improve the optical performance of DFB lasers.

It's known that Holographic polymer dispersed liquid crystal (HPDLC) gratings has been developed from 1993 and HPDLC can be used in optical communications, reflective flat panel displays, optical switches, organic lasersand other applications.

HPDLC gratings are fabricated by exposing a mixture composed of a photosensitive monomer and a LC to an interference field created by two coherent laser beams by the photo polymerization induced phase separation (PIPS) method. The alternating layers of the polymer and the phase separated LCare formed corresponding to the interference patterns.Organic distributed feedback (DFB) lasers based on HPDLCs are one of well-known novel HPDLC applications recently. HPDLC gratings can be used as cavities or external feedback layers. Compared with other fabrication techniques of organic DFB laser, DFB lasers based on HPDLCs exhibit merits like easy fabrication, simple optical construction and tunable capability by external fields.

Polymer scaffolding morphologic HPDLC transmission gratings were studied for DFB laser applications, since this type grating exhibit high diffraction efficiency, low scattering loss and high degree of phase separation. The scattering loss is less than 6%, meaning that more efficient light pumping and light feedback can be achieved and higher conversion efficiency of pumping input to lasing output can be achieved.

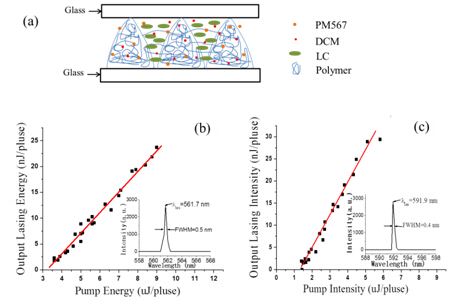

DFB HPDLC lasers using dye blends (PM567 andDCM) as gain medium has also been studied to form an efficient Forster energy transfer system. The Forster energy transfer from host emitter to guest emitter has been demonstrated an effective way to enhance the device performance.The lowest threshold energy (1.35) in the 10% DCM in PM567 doped system reduced by factor 2 compared to that without energy transfer process (2.75). However, Dyes need substantial dilution to avoid quenching, which reduces conversion efficiency of pumping light.We adoptedsemiconducting material (MEH-PPV) as a gain medium in polymer DFB HPDLC lasers.

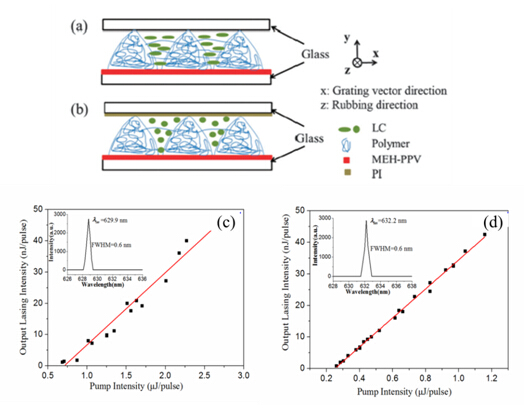

The neat 75 nm MEH-PPV film could absorb about 70 % pump light,andthe threshold of second-order DFB MEH-PPV HPDLC laser was 13.3, which was less than one-tenth of that from dye-doped DFB HPDLC laser.To further improve laser performance of DFB lasers, increasing the feedback efficiency was proposed. Alignment layer such as a rubbed polyimide (PI) layer adopted on the substrate can be used to increase the index difference in HPDLC.For three-order MEH-PPV DFB laser, the threshold of the lasing was reduced from 0.71 to 0.25 , and the conversion efficiency was increased from 2.3% to 4.6%.

HPDLCs can be used for various optical-electrical and opto-optical devices.The merits of simple configuration, commercially available materials, easy fabrication, and potentials to compact laser applications of organic laser based on HPDLCs will provide impetus to more research and practical applications.

Figure 1.(a) Schematic configuration.Output lasing intensity as a function of pump intensity for the DFB laser fabricated: (b)with pure PM567,(c)with 10%DCM in PM567,. The insets show the corresponding lasing spectra, respectively.(Image by CIOMP)

Figure 2.Device structures of (a) without the PI alignment layer and (b) withthe PI alignment layer.Lasing output intensity as a function of pump intensity for the DFB laser: (c) normal sample (d) sample with rubbed PI layer and low functional monomer. The insets show the corresponding lasing.(Image by CIOMP)

Contact

LIU Lijuan,

State Key Laboratory of Applied Optics, Changchun Institute of Optics, FineMechanics and Physics, Chinese Academy of Sciences, Changchun, 130033, China.

Tel: 86-321-86716016

Email: llj2007weihai@163.com