Author: |

Editor: YUAN Gan | Oct 11, 2021

Hydrophobicity is defined when the contact angle of a water droplet on the surface is great than 90°; and superhydrophobicity is defined when the contact angle is greater than 150° with a sliding angle smaller than 10°. The superhydrophobic property of lotus leaf is due to nano/microstructures on its surface and the low surface energy. These two factors can also be applied to other materials to make superhydrophobic surfaces for dealing with corrosion problems.

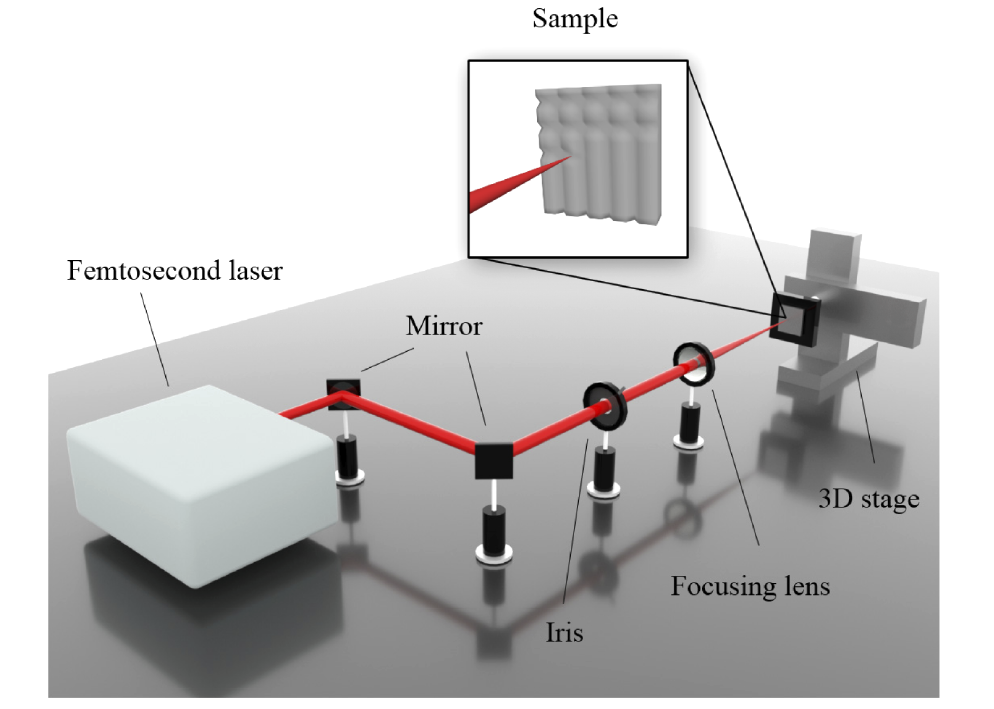

In a study published in Optics Express, a research group of the GPL Photonics Laboratory introduce a combination of femtosecond laser ablation and heat treatment post-process, without using any harsh chemicals. This research group comes from Changchun Institute of Optics, Fine Mechanics and Physics (CIOMP) of the Chinese Academy of Sciences.

They firstly used femtosecond laser to fabricate micro/nano structures on aluminum surface. After laser fabrication the aluminum surface shows superhydrophilic property. Then using 30 minutes heat treatment the aluminum surface turns from superhydrophilic to superhydrophobic without any chemical coating.

This is significantly shorter compared to conventional aging process of laser-ablated aluminum. The superhydrophobic surfaces maintain high contact angles greater than 160° and low sliding angles smaller than 5° over two months after the heat treatment.

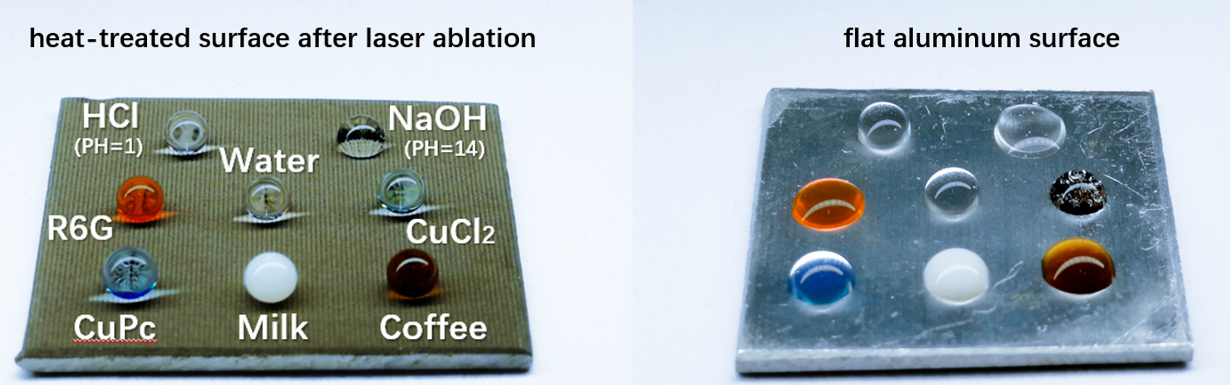

The superhydrophobic surface also exhibit strong superhydrophobicity for various types of liquids (milk, coffee, CuPc, R6G, HCl, NaOH and CuCl2). These liquids are very easy to slip off the superhydrophobic surface of the sample like a ball.

The samples also show excellent self-healing property. The superhydrophobic samples were cleaned under ultrasonic at 40 °C for 4 hours, they became hydrophobic and hydrophilic in different positions. After ultrasonic cleaning, samples were put in the room condition for 6 hours or put on the hot plate at 100 °C for 2 minutes. They recovered their superhydrophobicity, called as self-healing effect.

Putting the samples into the 5 wt % copper (II) chloride solution for 3 minutes, the superhydrophobic aluminum surface did not appear the red color on the fabricated area. It means that the sample after femtosecond laser and heat treatment exists the anti-corrosion property.

Auther: YUAN Gan

Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences

Changchun, Jilin 130033, China

E-mail: yuangan17@mails.ucas.edu.cn

Article links: https://doi.org/10.1364/OE.400804

Fig. 1. The schematic diagram of the femtosecond laser system (Image by YUAN)

Fig. 2. Liquid repellency with various types of liquids on the heat-treated surface after laser ablation and flat aluminum surface (Image by YUAN)