Author: |

Micro/nano structures are playing an increasingly important role in photonic crystals, metamaterials, and anti-reflective surfaces. Due to their research value, the periodic surface structure induced by laser radiation is gradually applied.

Generally, the period of the microstructures produced via the long-pulse laser is approximately the wavelength of the incident laser. For formation mechanism of these structures, most researchers believe that it is caused by the interference between incident light and scattered light. However, our studies demonstrate that the period of microstructures fabricated through nanosecond laser irradiation is close to 60 times the wavelength. Furthermore, we found that multiple rows of microstructures can be manufactured by changing the laser fluence when single-beam irradiation, and the period of the microstructure does not change as the peak power density. Therefore, to further explore the formation mechanism and characteristic of microstructures, it is quite necessary to carry out experiments to manufacture microstructures by a long-pulse laser.

In a study published in Optics Express, Prof. ZHANG Zhiyu and his PhD student REN Yingming from Changchun Institute of Optics, Fine Mechanics and Physics (CIOMP) of the Chinese Academy of Sciences (CAS) created an original microstructure on the silicon film surface by nanosecond laser irradiation. In addition, analyzed the formation mechanism of microstructures of various dimensions under the application context of the microstructures.

In this study, to clarify the characteristics of the microstructures, nanosecond laser fabricated microstructures on silicon film surfaces were analyzed by single-and multi-beam laser irradiation experiments. The results show that the number of microstructures columns is controlled by the peak power density during single-beam irradiation. Additionally, when peak power density is 4.65×109 W/cm2, the period of the microstructures can be customized by changing the scan pitch of the beam. Based on this, an approach of manufacturing microstructures with different periodicities in a large region is proposed.

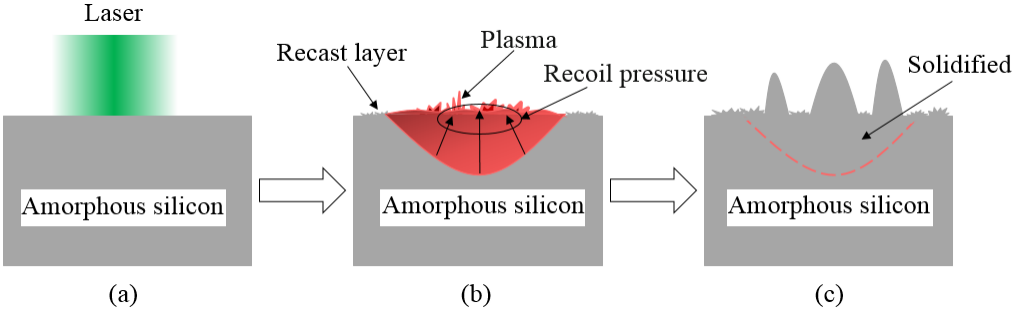

Based on the above structures, a formation mechanism of microstructures with various sizes is proposed in this paper. Under the continuous pulse impact, the central zone of the solid/liquid interface bulges when repetition rate is 140 kHz. When the bulge becomes larger, the protrusion forms an arc because of the surface tension effect. On the other hand, when the peak power density is enhanced to 1.55×1010 W/cm2, the laser-induced plasma causes greater recoil pressure and melted region, which allows the melted material to easily move above the initial surface. Finally, the comb-like structures are formed on the silicon film surface.

Fig. 1. Micro-protrusion formation mechanism for various laser peak power intensities (Image by REN)

Fig. 2. Mechanism underlying the formation of comb-like protrusions under a peak power intensity of 1.55 × 1010 W/cm2 (Image by REN)

Contact:

Author: Prof. ZHANG Zhiyu

Changchun Institute of Optics, Fine Mechanics and Physics (CIOMP), Chinese Academy of Sciences (CAS)

Changchun, Jilin 130033. China

E-mail: zhangzhiyu@ciomp.ac.cn

Article links: https://doi.org/10.1364/OE.434313