Author: |

Editor: LI Panyuan | Nov 24, 2021

In recent years, micro-LED displays have attracted increasing research and commercial attention because of their unique advantages, including high resolution, low power consumption, high brightness, and flexibility. In order to meet the application requirements of full-color micro-LED display, it is necessary to optimize the fabrication process to produce high-performance display devices.

Generally speaking, a range of commonly methods have been widely used to realize full-color micro-LED including growth, transfer printing, and color conversion techniques. Color conversion technique uses full-color micro-LED structures composed of blue/violet excitation light sources and red and green color conversion pixels. The color conversion layers are generally produced via inkjet printing and photolithography. These methods use different techniques to promote the development of full-color micro-LED, but there are some problems that need to be solved urgently.

In order to overcome the problem and fabricate high-performance display devices, this research proposes a method for fabricating quantum dot color conversion layers (QDCCLs) using microfluidics.

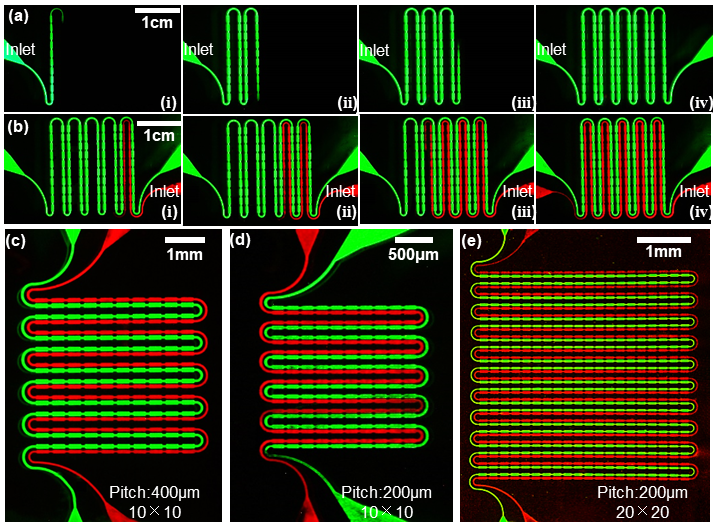

In this method, QDCCLs for full-color micro-LED display were successfully fabricated using microfluidics. The QDCCLs with full-color pixel size of 200 × 200 μm and sub-pixel size of 140 × 50 μm was achieved. Perovskite quantum dots (PQDs) with high quantum yield and narrow full width at half-maximum were used as the color conversion materials.

In the QDCCLs, the QY of the green and red PQDs were 90% and 51%, respectively, and their FWHMs were narrow at 14.2 and 23.8 nm, respectively. In order to achieve high fluorescence conversion efficiency and wide color gamut, we studied the change of fluorescence spectra at different concentrations. By choosing an appropriate PQDs concentration, a wide color gamut of 131% NTSC was achieved.

Compared with inkjet printing and photolithography methods, this method has the advantages of high precision, controllable pixel shape, and high utilization rate of PQDs. This method can further improve the display quality of full-color micro-LED and promote the commercialization of micro-LED.

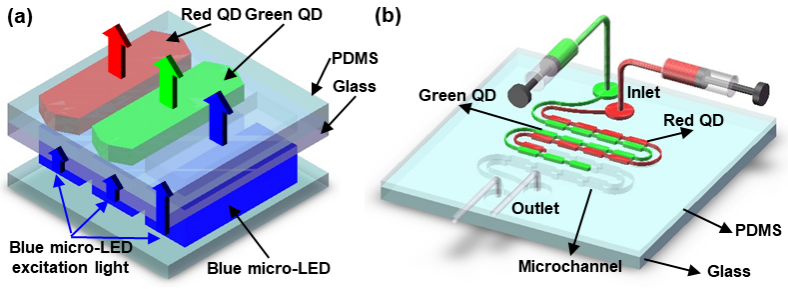

Fig. 1. (a) Schematic diagram of a single pixel of the full-color micro-LED display. (b) Red and green PQDs are injected in the micro-channels by syringes.

Fig. 2. (a) Fabrication process for the green QDCCL and (b) red QDCCL. (c) QDCCLs with full-color pixel pitch and a pixel number of 400 μm and 10 × 10, (d) 200 μm and 10 × 10, and (e) 200 μm and 20 × 20.

Contact:

Author: Associate Prof. JIN Tao

Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences

Changchun, Jilin 130033, China

E-mail: taojin@ciomp.ac.cn

Article links: https://aip.scitation.org/doi/10.1063/5.0047854