Author: LI Mingzhuo |

In a study published in Optics Express, a research group led by ZHANG Xuejun from Changchun Institute of Optics, Fine Mechanics and Physics (CIOMP) of the Chinese Academy of Sciences (CAS) proposed a new strategy of improving the instrumental transfer function (ITF) of the CGH interferometric null test.

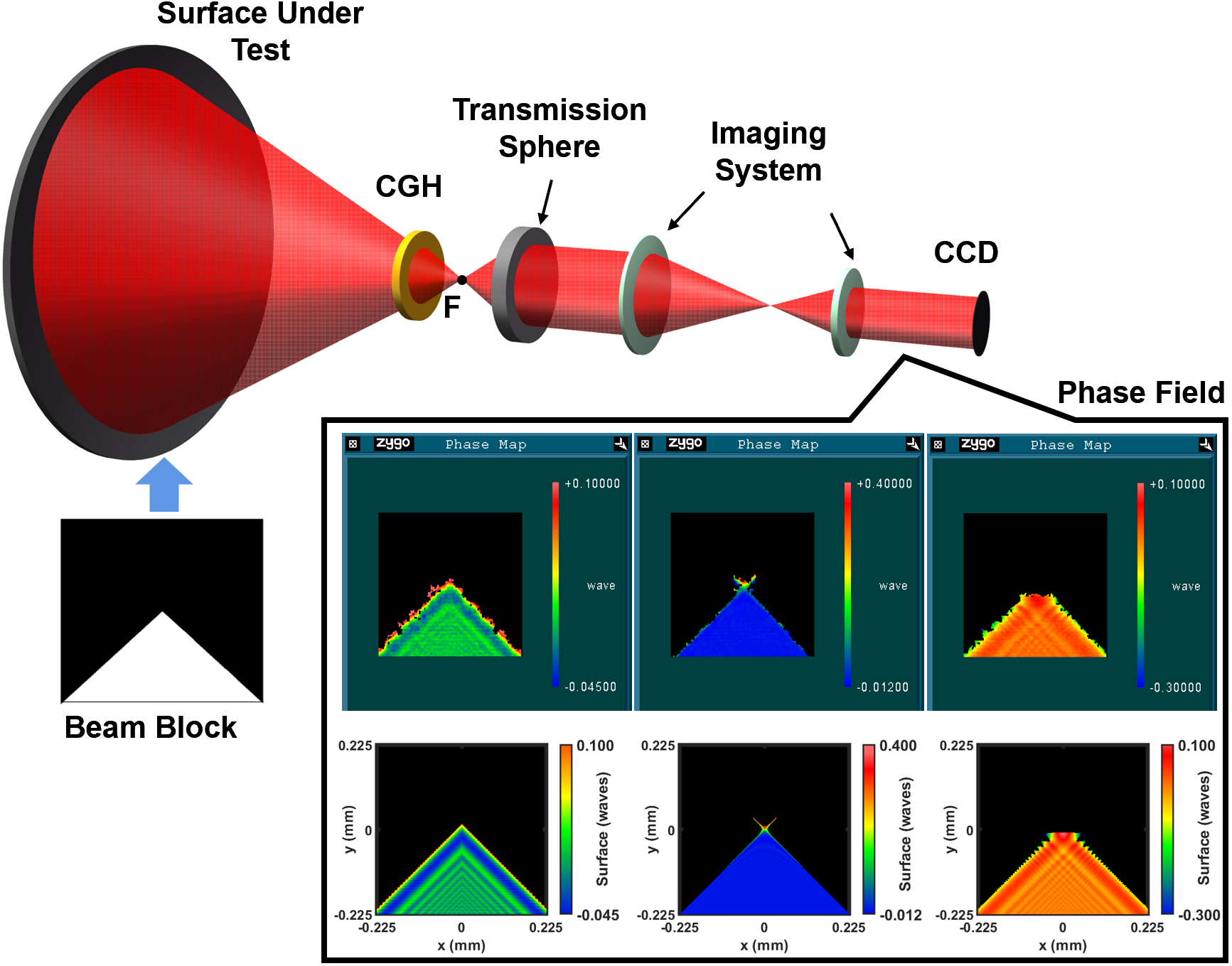

Fig.1 Comparison of phase field in the interferometric null test by measurement and simulation (Image by LI).

The computer-generated hologram (CGH) modifies the test wavefront in the interferometric null test with nano-meter precision to achieve nanometer scale measurement of optical surface error.

In the high-accuracy fabrication of large optics, researchers found that the CGH will introduce interferometric imaging aberrations into the optical path. The surface measurement is degenerated by the corresponding diffraction effects, resulting in the limitation of the ITF. The response of surface error feature with mid-&high spatial frequency would be cut-off.

Thus, the surface measurement cannot be used as a guide for deterministic surface processing. The wavefront degeneration of CGH is the key to the development of optical fabrication towards larger optics and ultra-high accuracy.

Scientists from CIOMP proposed a model based on the complex ray tracing method with elliptical Gaussian beamlets, which provided a direct and precise mathematical description of the wavefront degeneration in the optical system.

According to this model, they derived a parametric analytical equation of the ITF directly related with the parameters of the optical system. They apply the method in optimizing the optical system of null test for a 3m aspheric mirror. The degeneration of the test wavefront in the mid-&high spatial frequency regime is suppressed significantly. Therefore, the cut-off frequency of the CGH null test is extended in the high spatial frequency regime.

According to the model above, people could detect finer features with high spatial frequency of the optical surfaces. Thus, people is adventuring towards the fabrication of larger and more complex optical surfaces with ultra-high accuracy and precision.

HU Haixiang

Changchun Institute of Optics, Fine Mechanics and Physics

E-mail: hhx@ciomp.ac.cn